|

| May 21, 2019 | Volume 15 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Designing with threaded metal inserts for plastics

By Bob Gallagher, PennEngineering®

When deciding how best to attach plastic materials or components in an assembly, designers can choose several options, including adhesives or rivets. But what if disassembly and reassembly will be necessary for the unit down the road? In many cases, such fixed and unyielding joining methods will quickly be ruled out. The more practical solution: threaded metal inserts.

Permanently mounted where designed into ABS, polycarbonate, and other plastic substrates, metal inserts ultimately provide durable and reusable threads to accept mating hardware. Inserts also create a strong and sturdy joint, and enable repeated disassembly and re-attachment without damaging the insert's threads or compromising an assembly's integrity.

Applications abound, including compact consumer electronics assemblies (wearables, smartphones, handheld devices) and plastic components for the medical, automotive, aerospace, transportation, and recreational industries, among many others.

Surveying the universe of threaded metal inserts, designers can narrow the field for an application by evaluating the various insert mounting techniques, designs, materials, and sizes to arrive at appropriate choices.

Mounting methods and designs

Threaded metal inserts can be classified, in part, by how they are installed. Here is an overview, including various insert designs within each category:

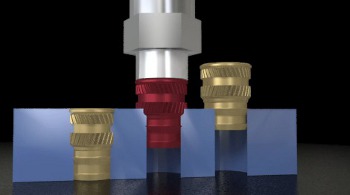

- Ultrasonic inserts are installed by pressing the insert into a pre-formed mounting hole using ultrasonic insertion equipment, while simultaneously applying a high-frequency vibration. Frictional heat caused by the vibration melts the plastic surrounding the insert and allows easy insertion. When the vibration ceases, the plastic solidifies, locking the insert permanently in place. Click here to view ultrasonic installation or see below.

Ultrasonic inserts are typically "thru threaded" (open at both ends) with tapered, straight, or symmetrical walls. Tapered versions are designed for use in tapered holes, allowing for rapid and accurate alignment prior to installation; straight wall inserts integrate a self-aligning lead-in providing for accurate alignment prior to installation; and symmetrical designs accommodate either straight or tapered holes and eliminate a need for orientation during installation.

- Heat staking inserts are installed by pressing the insert into a pre-formed mounting hole and heating it with a thermal press to melt a small portion of the hole periphery as the insert is being pressed into the part. The softened resin then flows into the insert's knurl pattern and hardens to form a firm bond. As with the ultrasonic inserts, these thru-threaded inserts are engineered with tapered, straight, or symmetrical walls. Click here to view heat staking installation or see below.

- Molded-in inserts are installed during the molding process. These inserts are located in the mold cavity by core pins. When the mold opens, the core pins are withdrawn, leaving the inserts permanently encapsulated in the plastic section with only the threads exposed. Since installation is performed during the molding process, there is no need for any secondary steps or special auxiliary equipment. See installation below.

Molded-in types include "blind threaded" (closed on one end), which protects threads from plastic intrusion, and thru-threaded versions. Self-locking blind threaded inserts feature purposely altered threads creating a prevailing torque locking feature to prevent mating screw loosening due to vibration. With thru-threaded fasteners, the pilot diameter and undercuts allow plastic to flow into grooves, providing high pullout resistance. Click here to view molded-in installation.

- Press-in inserts are installed by simply pressing the insert into a pre-drilled hole using any standard press during the production process. This method eliminates a need for applying heat or using ultrasonic equipment. Click here to view press-in installation or see below.

These thru-threaded inserts are especially distinguished by design variations, including a hexagonal "barbed" configuration ensuring resistance to force in both directions and exhibiting high torque-out and pullout values, slotted versions that compress to allow easy access into the mounting hole, flange-head inserts eliminating direct contact of plastic with mating parts, and inserts with straight knurls at their top end promoting higher torsional resistance.

Regardless of insert type, the knurling pattern -- cut or rolled by the manufacturer onto the outside of an insert -- is critical, directly impacting pullout and torque-out resistances in service. (Pullout is the force required to pull the insert from the host material, and torque-out is the torque required to turn the fastener in the host material after installation without inducing clamp load on the fastener.)

As general guidelines, straight knurls (parallel to the length of the insert) offer the greatest resistance to torque, but less for pullout. (Engineered grooves between knurl bands can increase pullout resistance.) Diagonal, or helical, knurls balance resistance to forces in both directions, and hexagonal, or diamond-shaped, knurls resist forces in all directions.

Materials and sizes

Threaded metal inserts for plastics are manufactured from brass (the most commonly used material), stainless steel, or aluminum -- and recent advances have made significant material differences for applications.

Lead-free threaded metal inserts made from aluminum or stainless steel offer alternatives to leaded brass versions in addressing potential environmental and end-of-life recycling concerns.

As examples, lead-free stainless steel and aluminum inserts have been introduced as alternatives to leaded brass to address potential environmental and end-of-life recycling concerns. Lead-free fasteners have been made possible by applying new materials, processes, and tool technologies without compromising fastener quality and performance.

In contrast to brass counterparts, stainless steel inserts are typically stronger and may offer better protection from corrosion, while inserts made from lead-free aluminum are approximately 70 percent lighter than brass equivalents to promote lighter designs.

Turning to size, inserts are available in a standard product line range from about 1/8 in. to 9/16 in. in diameter and 1/8 in. to 5/8 in. in length, with unified or metric thread sizes ranging from #0-80 to 3/8-16 and M2 to M10, depending on type.

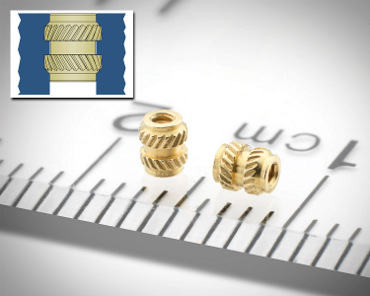

Micro-sized threaded metal inserts have been developed as small as 1 mm in diameter and 1.75 mm in length to provide ideal solutions for physically smaller plastic assembly applications, such as handheld devices.

For physically smaller applications, such as with handheld devices and other compact consumer electronics, brass and lead-free aluminum inserts have been developed as small as 1 mm in diameter and 1.75 mm in length. These tiny inserts with a symmetrical design (eliminating the need for orientation during installation) can accommodate an M1 fastener (the smallest ISO-designated M-profile thread) and can be installed with a heat staking or ultrasonic process in straight or tapered holes.

With all the many types and designs, threaded metal inserts offer designers a vast array of possibilities. In the event that an application may require specialized or custom fasteners, a recommended rule of thumb is to partner early in the design process with an established manufacturer. The resulting know-how and engineering support can make all the difference in successful outcomes.

Click here for a complete catalog on threaded inserts for plastics.

Bob Gallagher is SI® Product Manager overseeing the SI brand of threaded metal inserts at PennEngineering®, 5190 Old Easton Road, Danboro, PA 18916-1000 USA. Contact him at bgallagher@pemnet.com or +1-215-766-8853. www.pemnet.com.

Published May 2019

Rate this article

View our terms of use and privacy policy